Introduction

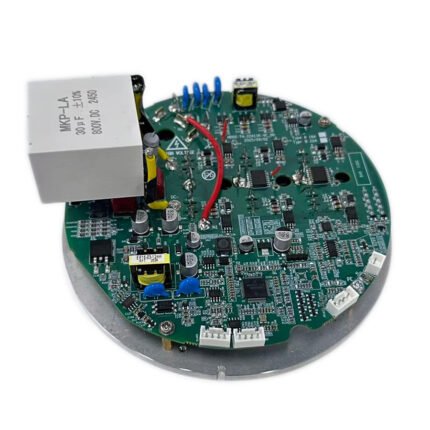

Name:EC permanent magnet synchronous drive universal adapter

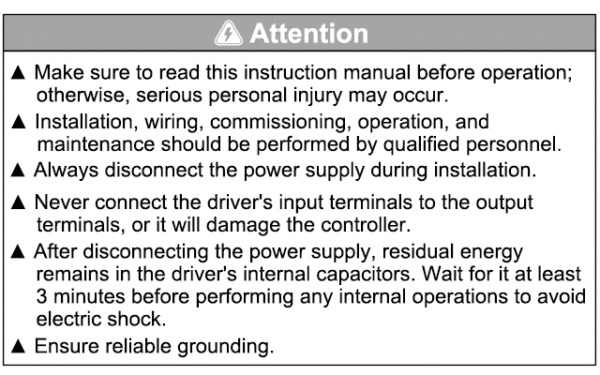

Thank you for your trust in our products. We will regularly review and update this manual, and we welcome any suggestions for improvement.

This application guide is intended for qualified personnel, such as automation engineers or application and product experts with experience and basic knowledge of inverter parameter operation.

To ensure you fully understand and use this series of products, achieve their best performance, and enjoy comprehensive after-sales service, please read this manual carefully before using the product to avoid inconvenience and accidents caused by incorrect operation.

This application guide provides information on drive-related control parameters and configurations, the host computer interface for operating the drive, typical application settings, and troubleshooting methods for possible alarms and faults.

- Product Introduction and Specifications

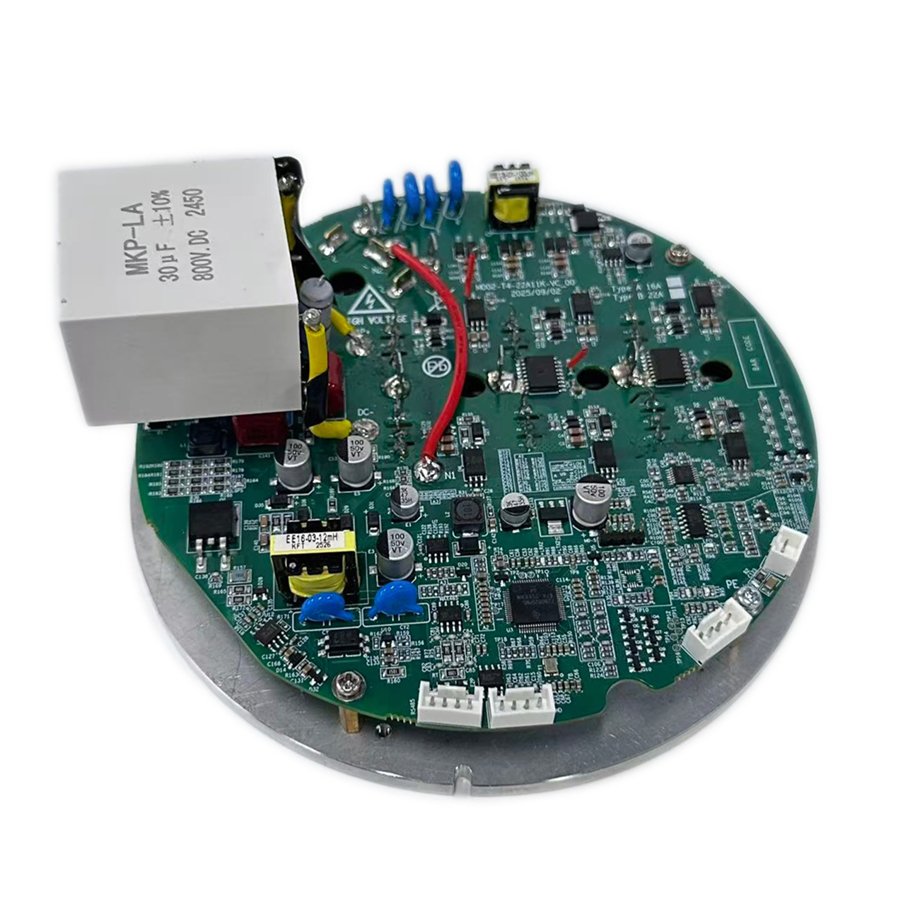

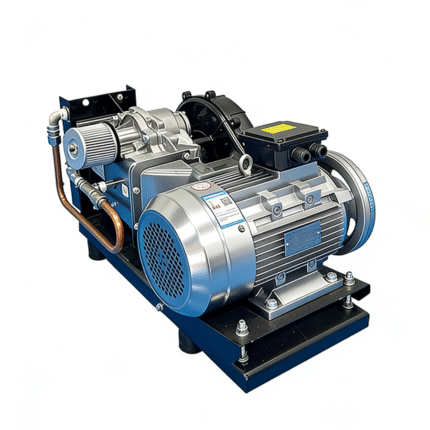

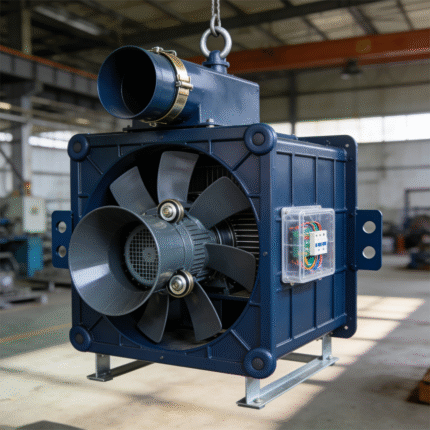

It is specifically developed for permanent magnet direct-drive industrial ceiling fans, and it can be adapted to various models of permanent magnet synchronous motors and different fan blade sizes. It is the most advanced direct-drive motor technology in China, featuring stepless speed regulation, speed tracking, and forward/reverse switching.

The DLX002 series controller is suitable for ventilation industry applications, such as factory industrial ceiling fans, negative pressure fans, and aquaculture fans. Catering to industry characteristics, it meets requirements for high air volume output, ultra-quiet operation, and high energy efficiency.There are so many advantages as follows,

- Simple and easy to use: clearinterface, convenient operation, beautifuland practical.

- High versatility: Automatically adaptable to various SPMSM motors (such as BLDC motors) and IPMSM; advanced FOC algorithm adapts to various load changes.

- High efficiency and energy saving: Optimal MTPA control (IPMSM only), lowtemperatureto extend motor life

- Smooth start: Optimized positioning + IF start mode for high pole pairs and large starting inertia, ensuring smooth start every time

- Speedtracking: For non-stationary or headwind starting conditions, speed tracking function ensures the motor starts smoothly without waiting to stop

- Safe and reliable: Comprehensive protection measures, including overcurrent protection, overvoltage protection, overheat protection, short circuit protection, and overload protection, improving system stability.

| Product Specifications | ||

| Product Model | DLX002-D4-2.2KW | |

| Input Voltage | AC 380V ± 10% | |

| Output Current | MAX 5A(RMS) | |

| Control Method | positioning Method | DC Positioning/High-Frequency Injection |

| operating Method | IF Start/Direct Start – FOC – Weak | |

| Magnetic Control | RS485 | |

| Dimensions | 248*123*85mm | |

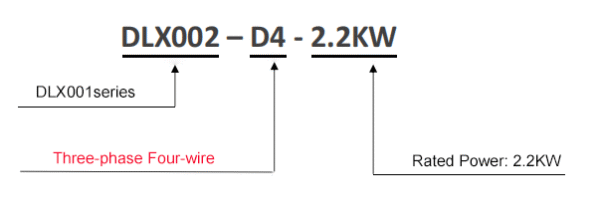

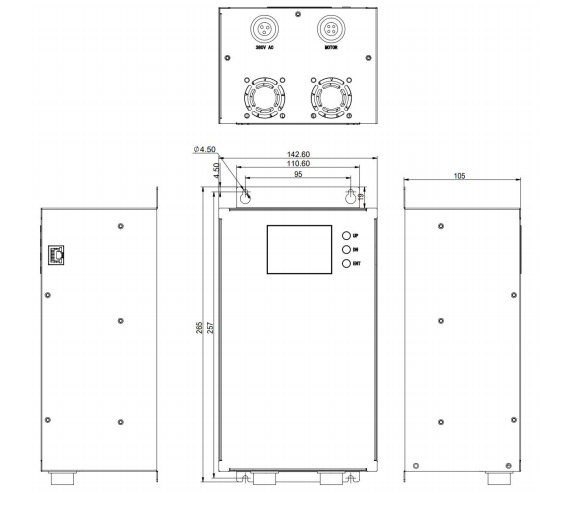

III. Product Model Description and Installation Dimensions

3.1 Model Description

3.2 Installation size

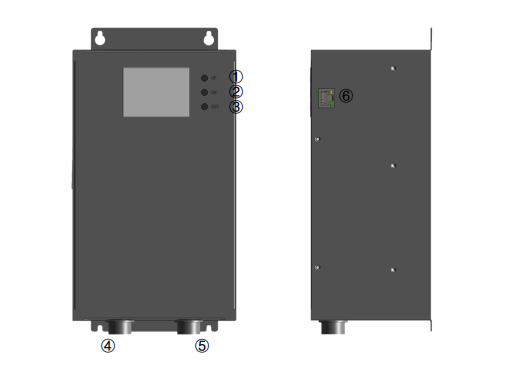

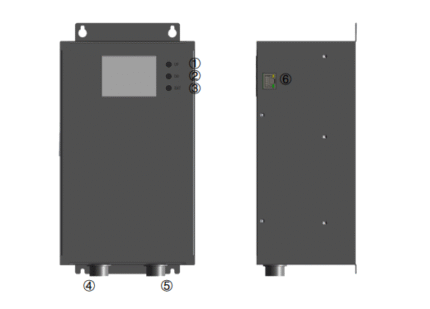

四、Key and Terminal Wiring Instructions

| Code | Terminal Sign | Terminal Name | Function |

| ① | UP | Plus | Start/Stop |

| ② | DN | Reduce | +Pole/-Pole |

| ③ | ENT | Confirm | Start/Stop/confirm |

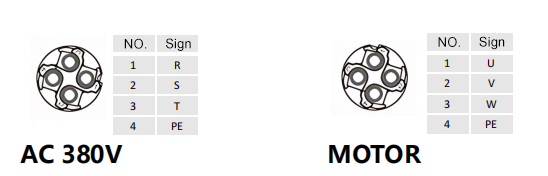

| ④ | AC 380V | LD20-Rev Conn | Power input |

| ⑤ | MOTOR | LD20- | Controller Input |

| ⑥ | RJ45 | Net Port Terminal | External Communication Module |

V.Panel Operation

5.1 Main Display & Operation

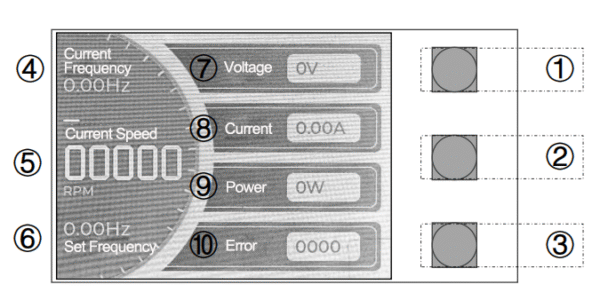

| ① | Plus/Up | Key |

| ② | Reduce/Down | |

| ③ | Start/Stop/confirm | |

| ④ | Current Frequency | Display |

| ⑤ | Current Speed | |

| ⑥ | Set Frequency | |

| ⑦ | Bus voltage value | |

| ⑧ | Set speed/frequency | |

| ⑨ | Output power | |

| ⑩ | Alarm |

After the equipment completes its power-on self-test, its operating status can be controlled and viewed in real time, enabling one-button start/stop of the equipment and speed control. It also provides real-time monitoring of various operating states and display of abnormal conditions.

Reviews

There are no reviews yet.